Abrasion testing plays a crucial role in evaluating the durability and performance of materials across various industries. Whether it’s assessing the wear resistance of automotive components, the durability of textiles, or the longevity of surface coatings, selecting the appropriate abrasion test method is essential for obtaining accurate and reliable results. In this guide, we’ll explore the factors to consider when choosing the right abrasion test method for your material and application.

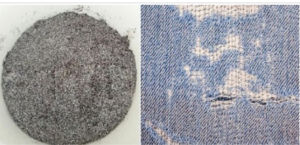

Understanding Abrasion Testing: Abrasion testing involves subjecting materials to mechanical wear under controlled conditions to simulate real-world abrasive environments. The goal is to quantify the material’s resistance to wear and determine its ability to withstand repeated rubbing, scratching, or scraping forces. Abrasion tests can vary significantly in terms of test parameters, equipment, and test procedures, making it essential to select the most suitable method for your specific needs.

Factors to Consider:

- Material Type and Properties:

- Consider the nature of the material being tested, including its composition, hardness, and surface characteristics. Certain materials may be more prone to abrasion than others, requiring specialized testing methods.

- Determine whether the material is homogeneous or heterogeneous, as well as its structural integrity and porosity, as these factors can influence abrasion resistance.

- Intended Application:

- Identify the intended use or application of the material and the types of abrasion it is likely to encounter in real-world scenarios. For example, materials used in high-traffic areas may require different testing methods than those used in low-impact environments.

- Consider any specific industry standards or regulations that govern abrasion resistance requirements for your application, such as ASTM, ISO, or DIN standards.

- Abrasion Mechanism:

- Understand the predominant abrasion mechanism that the material will be subjected to, whether it’s abrasion caused by particulate matter, sliding or rubbing contact, or repetitive mechanical action. Different test methods simulate various abrasion mechanisms more accurately than others.

- Test Parameters and Conditions:

- Evaluate the test parameters and conditions, including test load, speed, duration, and contact geometry. These factors can significantly impact test results and must be tailored to mimic the intended application environment.

- Consider environmental factors such as temperature, humidity, and chemical exposure, as these can affect material performance and abrasion resistance.

Choosing the Right Test Method: Based on the above considerations, select the abrasion test method that best aligns with your material properties, application requirements, and testing objectives. Some common abrasion test methods include:

- Linear Abrasion Test

- Dry Sand/Rubber Wheel Abrasion Test

- Wet Abrasion Test

Choosing the right abrasion test method is essential for accurately assessing the wear resistance and durability of materials. By considering factors such as material properties, intended application, abrasion mechanism, and test parameters, you can select the most appropriate test method to ensure reliable and meaningful test results. Consult with abrasion testing experts to determine the optimal testing approach for your specific material and application needs.

Leave a Reply